– Clear

“Stone Age,” “Iron Age,” “Silicon Valley” – these terms reflect major aspects of human civilization. From textiles to sugar, to transistors and smartphones – various products have proven critical developments in human history. What materials made them possible? What new industries did they spawn? What new problems did they create? What might come next?

Section 120: The Greatest Materials of All Time

How can we make engineering more sustainable and more beneficial to people and the environment? If that’s a question you care about, this is the E100 section for you. This is a course about sustainable materials and user-centered engineering design. Our goal is to teach sustainable engineering practices that will be useful to nearly all engineers.

Section 130: Sustainable Materials and User-Centered Design

A river runs through natural settings, a river runs through urban environments. Most rivers in the world have been impacted by human activities. Our goal is to gain a solid understanding of river dynamics and related ecosystem services. As engineers, we will learn methods and tools to restore habitats for certain aquatic species, stabilize banks, and rehabilitate important natural functions in urban streams.

Section 150: A River Runs Through It

Cities hum through neighborhoods and skylines, alive with people, infrastructure, and nature. This course reveals the interwoven systems—water, energy, transportation, public services—and shows how AI, sensors, and data reshape urban life. You’ll learn to identify citizen needs, explore real-world smart city innovations, and design technology solutions that boost sustainability and engagement.

Section 190: Smart Cities

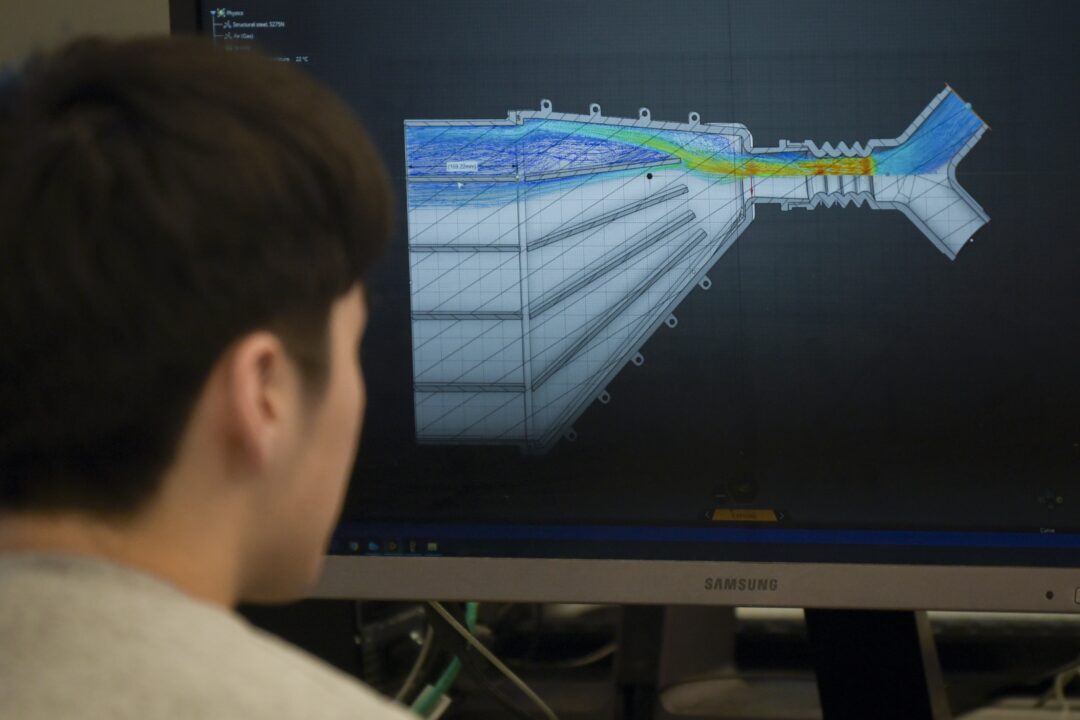

This course provides a detailed overview of the engineering design process – the “heart” of engineering – in a broadly accessible manner that assumes no specialized knowledge and is largely applicable to most engineering disciplines. Students also learn various practical skills commonly employed in the design process such as basic CAD and CAE, TRIZ techniques, patent searching, and project management software.

Section 200: Design in the Real World

Instructors from five different disciplines will support your exploration of the creative design process through a collaborative, semester-long project: a multimodal essay, that combines architecture, art & design, engineering, music and writing to make an argument, while preparing you to work on interdisciplinary design teams.

Section 210: Writing and Interdisciplinary Collaborative Design

How do innovative technologies lead to new products? And how can you, as an engineer, identify valuable opportunities for new innovations? This section explores the intersections of engineering and business with a focus on identifying, developing, and evaluating the viability of new product opportunities for an innovative platform technology.

Section 220: Tech Revolutions: Innovation and the Creation of Value

Microprocessors and computing systems have become pervasive and have enabled the intelligent functioning of cars, chatbots, computers, phones, watches, websites, and countless other systems. In this course, you will build the hardware and software of a complete computing system, including the microprocessor, operating system-level code, and application program.

Section 250: Microprocessors and Toys

It is not an overstatement that computers are the most important technological achievement of mankind in the 20th century. With “smart” devices becoming part of our daily lives, engineers continue to advance every aspect of computing.

Section 270: Next Generation Computing Hardware

Machine learning is transforming the way engineers tackle complex challenges — from predicting structural failures to designing new medical technologies. In this section, you'll build a strong foundation in computational machine learning and discover how modern engineers use data-driven models to drive innovation.

Section 280: Computational Machine Learning for Scientists and Engineers

In this course, we will provide a comprehensive introduction to the captivating realm of wearable electronics.This course combines material physics, chemistry, and engineering, based on which we can create wearable electronics that are reshaping the future of renewable energy, healthcare, and soft robotics.

Section 330: The Rise of Wearable Electronics

This section of Engineering 100 introduces fundamental concepts of bioengineering, biotechnology, and chemical engineering, and provides students an understanding of how biological systems can be engineered to solve real-world problems such as the need for renewable energy and affordable medicine.

Section 350: Engineering Biological Solutions

Autonomous systems such as self-driving cars, robots, and drones are being used today in a wide range of applications, from search and rescue to smart farming, from package delivery to the future of mobility. In this section, you will design and validate an engineering solution to enable a novel application based on an autonomous drone using the AirSim engine drone simulator.

Section 400: Self Driving Cars, Drones, & Beyond

In this section of ENGR 100, students will learn about solar energy collection and storage, and more generally, about electrical circuits, micro-controllers, wireless technology, and energy/power. The first half of the class will teach concepts in each of these areas, where electrical systems provide information collection, processing, and networking for all engineering fields.

Section 420: Solar Energy and Self-Powered Wireless Systems

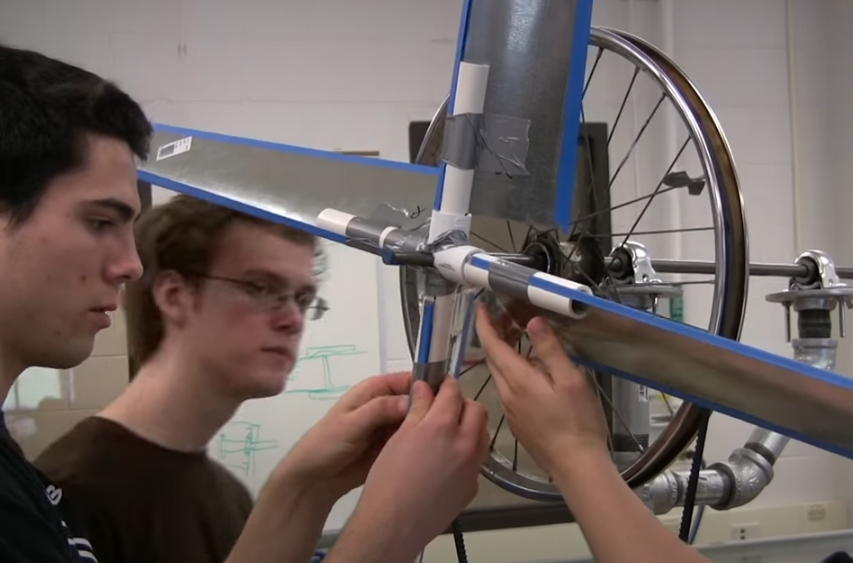

This section introduces students to the engineering profession by exploring the engineering challenges to using renewable energy as a “green” alternative to fossil fuels. Students learn concepts of renewable energy, culminating in a team-based term project to produce a device that scavenges wind energy to perform a task.

Section 450: Harness the Wind - Green Engineering

Wellness is a critical component of everyday life and includes both physical and psychological health. In this course we will explore research and technologies that support wellness, including wearable sensors. Wearable sensors let us track biometric data, which can be readouts of sleep patterns and emotions.

Section 520: Engineering Wellness: Technologies to Support Physical and Mental Health

Manufacturing is the cornerstone of our society. Manufacturing creates value and is the main driver of the local economy and good-paying jobs. During the COVID-19 pandemic, impacts of the shortage of integrated circuit (IC), also known as semiconductor chip or IC chip, on delivery and inflation are the most significant. Semiconductor manufacturing is essential for national security and economic growth.

Section 560: Semiconductor Manufacturing and the Society

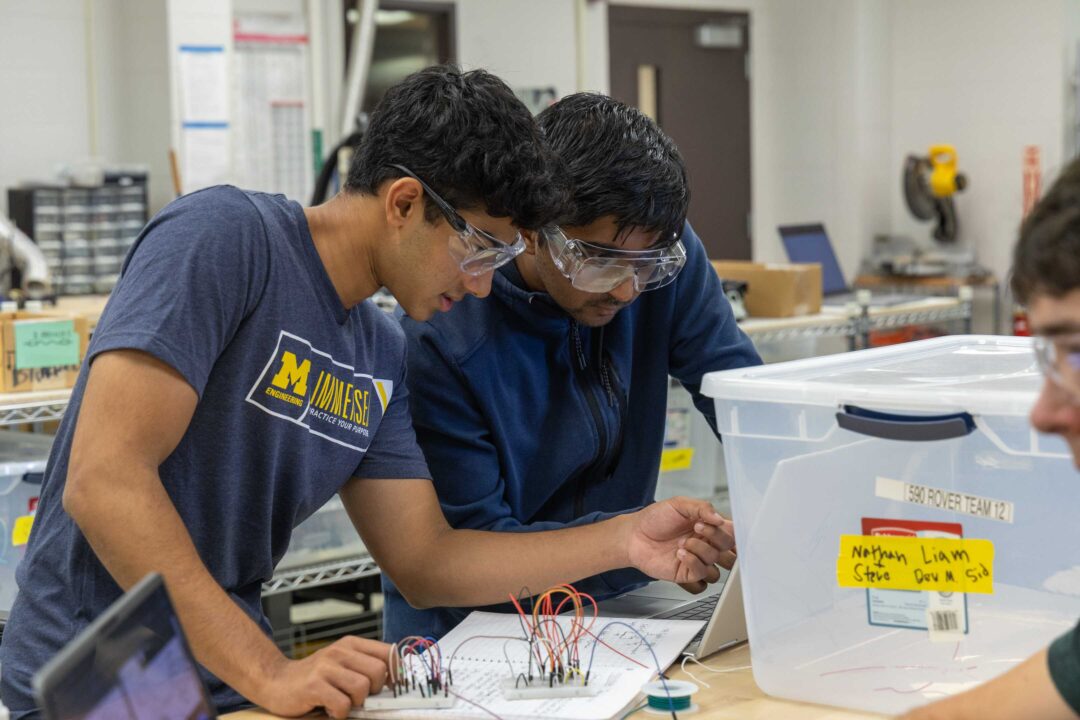

In our section, you will work in a team of five to design, build, test, and communicate about a remotely operated vehicle (ROV), sometimes called a submersible, for underwater exploration. The ROV has a set of tasks that it will need to do, but otherwise this is a “free design” project with minimal constraints on size, shape, and function.

Section 600: Underwater Vehicle Design

This course introduces students to practical Aerospace Engineering processes by the means of design, build, test and operation of simple flight vehicles (e.g. hovercraft). This Systems Engineering Experience includes an extensive design-build-test-compete component.

Section 700: Intro to Aerospace Engineering

Do you ever have to swipe your M card more than once to enter your dorm room? In essence, there is always room for improvement in everyday processes. Continuous improvement in processes and operations focuses on consistently applying methods that improve the quality of a product or service.

Section 810: Continuous Improvement & Operations Management

Robotics systems are beginning to serve a broad range of new and diverse roles in multiple aspects of modern society. But how are these robots designed and how are they developed?

Section 850: Robotics Mechanisms

Toys shape our worldview and mirror cultural values and practices. In this course, you’ll explore the science, engineering, and ethics of nuclear technologies to inform imaginative toy design. Leveraging 3D printing, textiles, metalwork, clay, found objects, and immersive VR, students iteratively prototype toys.

Section 920: Toys for the Third Nuclear Age

In this class, students will learn how to use a systems approach to build a sensor board using a micro-controller to take both in situ and remotely sensed observations of a high-altitude environment.

Section 950: Electronics for Atmospheric & Space Measurements

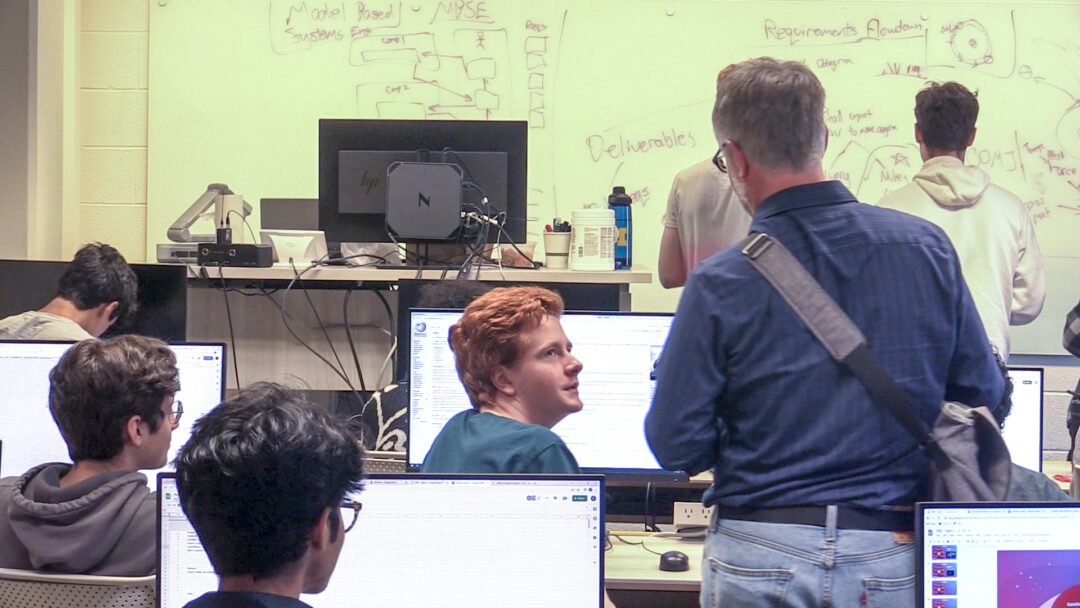

Rocket science, how we use rockets to move stuff around the Earth and throughout the solar system, is a confluence of several engineering fields including mechanical, aerospace, and electrical engineering as well as computer science. When a system is built, its performance is measured and compared against expectations given the design.

Section 980: Rocket Science